Bearings help parts move by reducing friction and keeping machines steady. They’re used in motors, wheels, fans, and tools where spinning or sliding happens. Without them, parts wear out fast. Each bearing type is designed to handle weight, direction, or speed in different ways.

This post explains the types of bearing with pictures and how they help machines do their job well.

Different Types of Bearing in Engineering

Bearings are divided by design and how they handle force and motion. Below is a list of common bearing types used in tools and machines across industries.

- Ball: Uses metal balls to lower friction between surfaces. Good for light to medium loads.

- Roller: Uses cylinders instead of balls. They handle heavier loads and offer better shock resistance.

- Plain: Lacks rolling elements. Sliding contact makes them great for slow or heavy operations.

- Fluid: Oil or gas layer reduces contact. Often used in turbines or high-speed rotating parts.

- Magnetic: Works using magnetic force to support the shaft. Ideal for high-speed or delicate systems.

- Jewel: Uses synthetic gems to reduce friction. Often found in watches or measuring instruments.

- Flexure: Made to bend slightly during motion. Used in precision tools where rolling isn’t possible.

- Pivot: Uses a pointed shaft and concave surface. Common in meters and measuring tools.

- Foil: Thin metal layers float on air. Found in micro turbines and aerospace fans.

- Tilt Pad: Has pads that adjust angle to support load. Used in large compressors and turbines.

Rolling Contact Bearing Types

These types use rolling elements between surfaces to handle load and motion. Below is a list of major rolling contact bearings used in machines.

- Cylindrical: Long cylinder rollers support radial loads. Suitable for electric motors and pumps.

- Tapered: Conical rollers manage both thrust and radial loads. Used in car hubs and machinery.

- Spherical: Rounded rollers allow for small misalignments. Found in gearboxes and heavy equipment.

- Needle: Long and thin rollers support heavy radial loads in small spaces. Used in transmissions.

- Toroidal: Mix of spherical and cylindrical shape. Ideal for applications needing both flexibility and load strength.

Bearings by Load Direction and Movement

This group explains how bearings respond to load direction and the kind of motion they allow. Below is a list based on those features.

- Radial: Handles force from the side of the shaft. Found in fans, alternators, and motors.

- Thrust: Manages force from the end of the shaft. Used in turntables, stools, and marine drives.

- Angular: Accepts load at an angle, combining radial and thrust forces. Common in pumps and machines.

- Linear: Allows straight line motion. Used in 3D printers, sliding tables, and CNC machines.

Types of Motor Bearing

Motor bearings support shaft rotation, reduce noise, and extend service life. Below is a list of types found inside different electric motors and appliances.

- Sleeve: A basic tube that holds the shaft in place. Found in fans and small motors.

- Ball: Handles combined loads and spins fast. Used in household tools and cooling fans.

- Sealed: Has built-in seals to keep out dirt and hold lubricant. Good for long-term use.

- Hydrodynamic: Uses oil film to support load. Suitable for large motors with high speed.

- Double Shielded: Has protection on both sides. Reduces contamination and keeps the motor running longer.

- Open: No shield or seal. Lubrication is applied from the outside, mostly in large systems.

Bearings for Specialized Applications

These are designed for unique environments or advanced machinery. Below is a list of special bearing types used in modern systems.

- Self-aligning: Adapts to misalignment between parts. Useful in shafts that aren’t perfectly straight.

- Air: Floats on air pressure without contact. Great for precision instruments and light rotary setups.

- Ceramic: Made from tough material. Can withstand high speeds and resist wear better than steel.

- Hybrid: Mixes ceramic balls with steel rings. Offers light weight, speed, and longer life.

- Super Precision: Gives accurate and smooth motion at high speeds. Used in CNC spindles and robotics.

- Thin Section: Very compact but strong. Used where space is tight, like in robotics or optics.

- Split: Can be opened for maintenance. Useful in heavy-duty industrial machines.

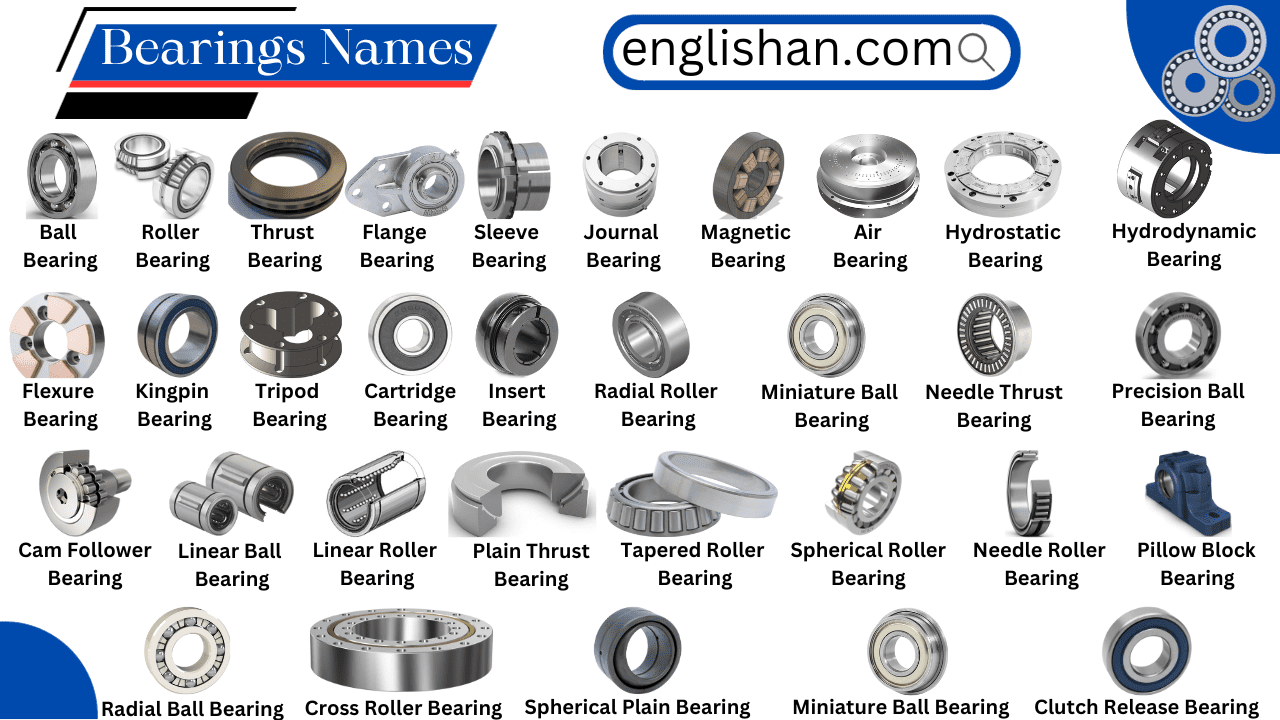

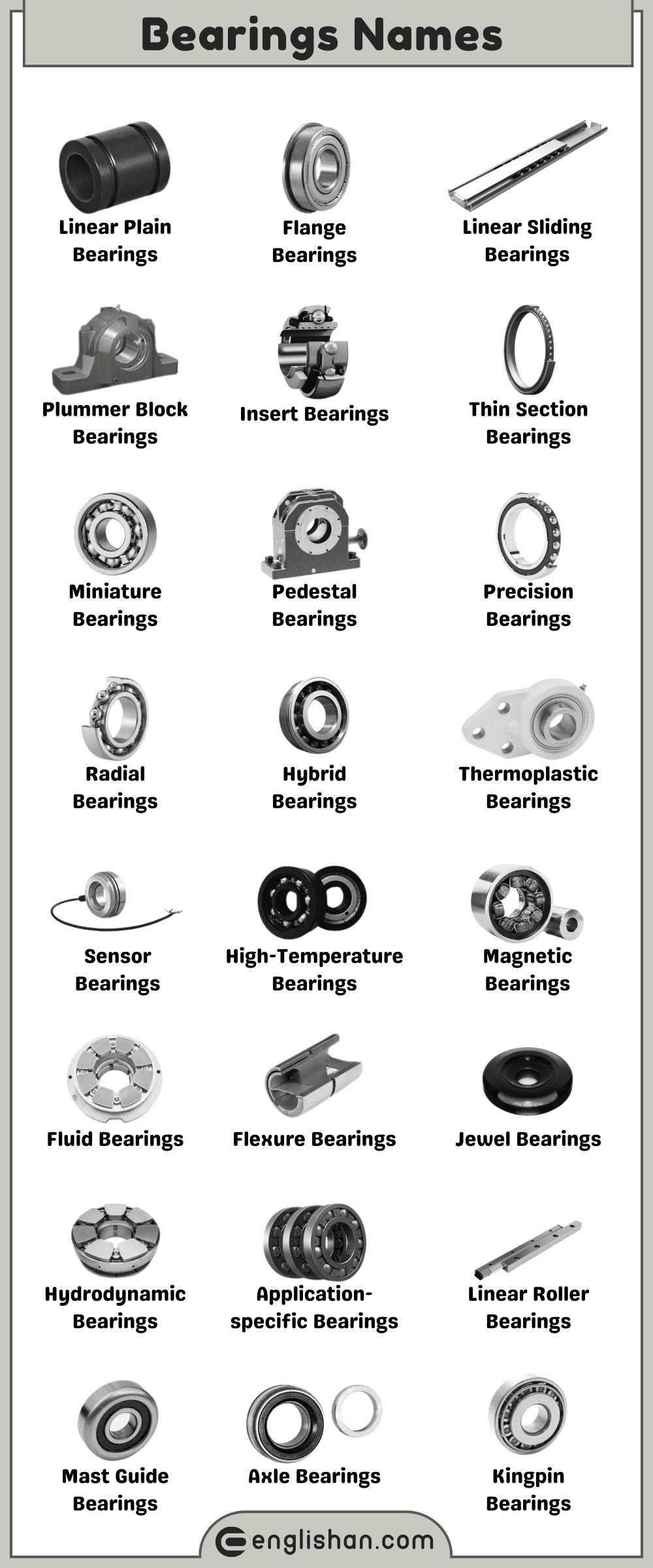

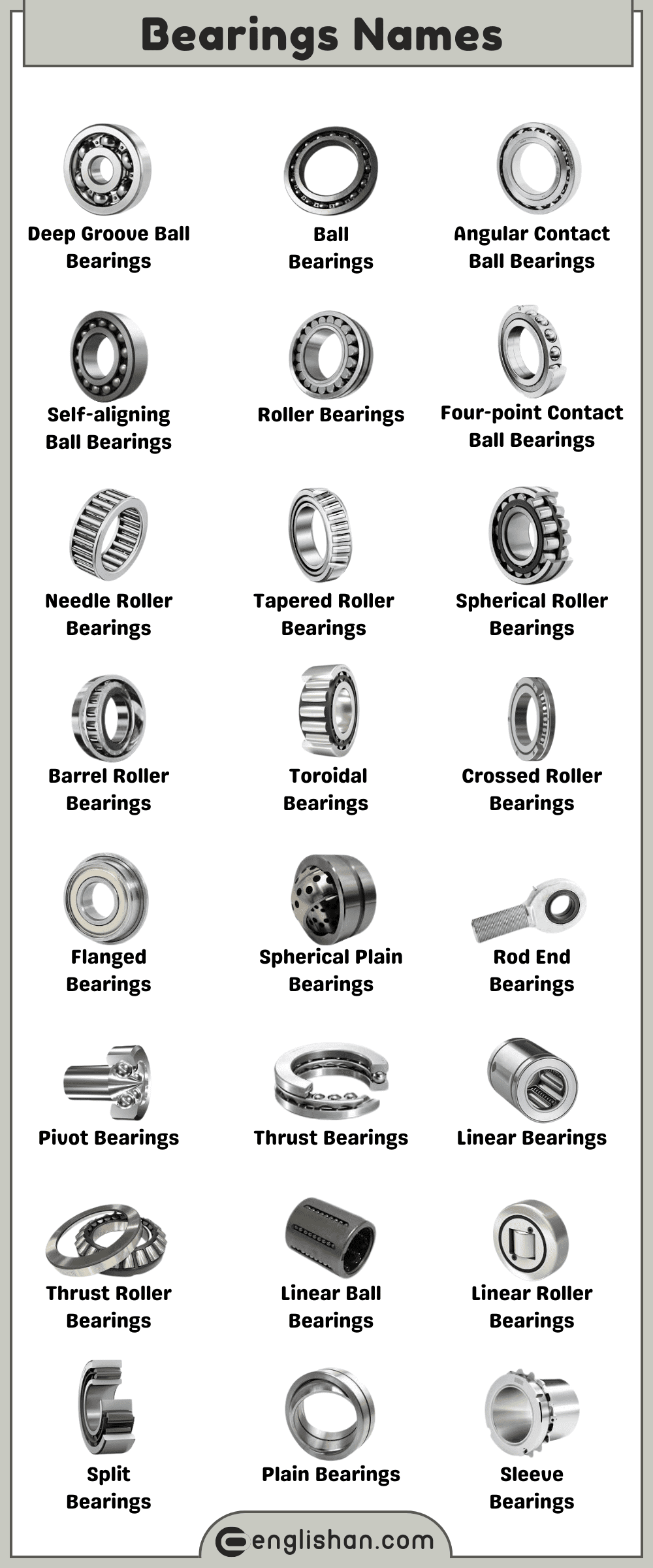

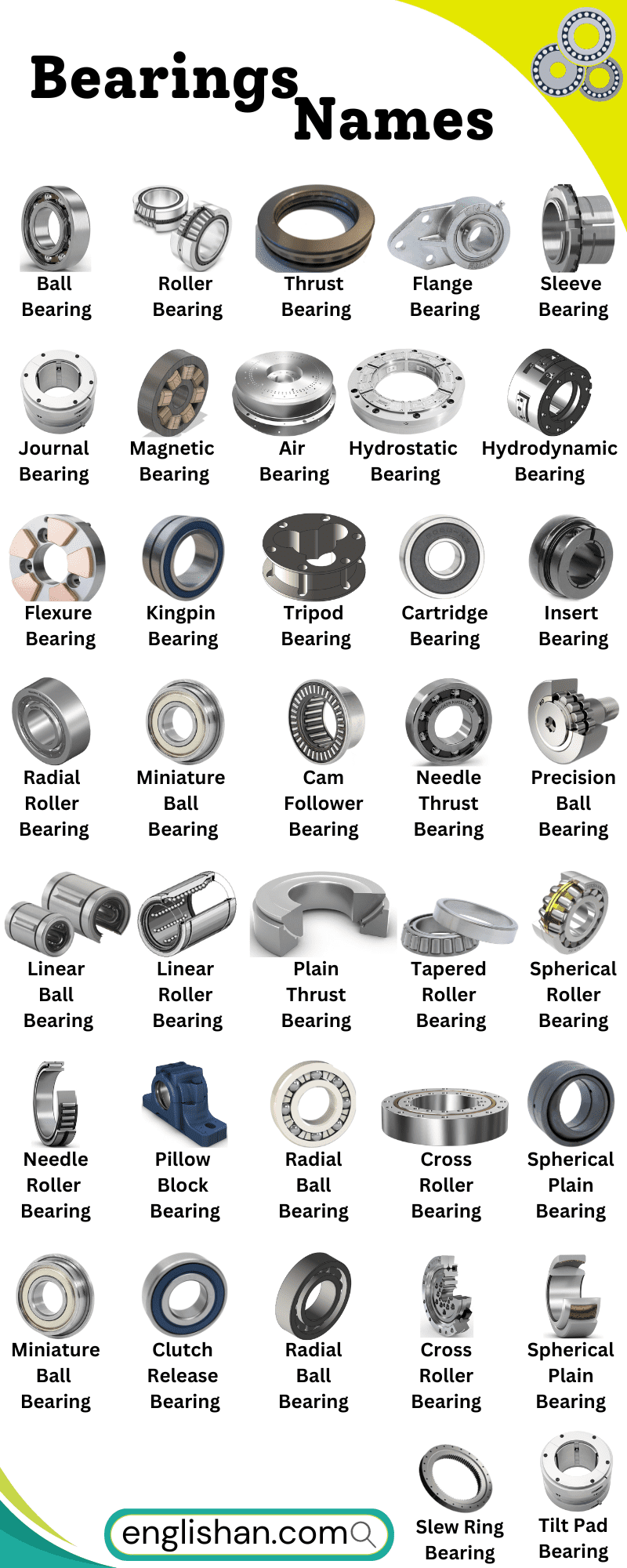

Types of Bearing with Images

Below is a complete chart of different types of bearing with pictures that match each name. These help you understand how each one looks and where it may be used.

List of Bearings Names

- Linear Plain Bearings

- Flange Bearings

- Linear Sliding Bearings

- Plummer Block Bearings

- Insert Bearings

- Thin Section Bearings

- Miniature Bearings

- Pedestal Bearings

- Precision Bearings

- Radial Bearings

- Hybrid Bearings

- Thermoplastic Bearings

- Sensor Bearings

- High-Temperature Bearings

- Magnetic Bearings

- Fluid Bearings

- Flexure Bearings

- Jewel Bearings

- Hydrodynamic Bearings

- Application-specific Bearings

- Linear Roller Bearings

- Mast Guide Bearings

- Axle Bearings

- Kingpin Bearings

- Integral Shaft Bearings

- Clutch Release Bearings

- Water Pump Bearings

- Track Roller Bearings

- Yoke Type Track Rollers

- Screw Drive Bearings

- Cam Followers

- Main Bearings

- Bicycle Bearings

- Fishing Reel Bearings

- Automotive Bearings

- Self-aligning Bearings

- Double Row Bearings

- Withdrawal Sleeves

- Freewheel Bearings

- Other Bearings

- Eccentric Bearings

- Bearing Housings

- Spindle Bearings

- Screw Thread Bearings

- Small Ball Bearings

- Super Precision Bearings

- Turntable Bearings

- Impact Bearings

- Deep Groove Ball Bearings

- Ball Bearings

- Angular Contact Ball Bearings

- Self-aligning Ball Bearings

- Roller Bearings

- Four-point Contact Ball Bearings

- Needle Roller Bearings

- Tapered Roller Bearings

- Spherical Roller Bearings

- Barrel Roller Bearings

- Toroidal Bearings

- Crossed Roller Bearings

- Flanged Bearings

- Spherical Plain Bearings

- Rod End Bearings

- Pivot Bearings

- Thrust Bearings

- Linear Bearings

- Thrust Roller Bearings

- Linear Ball Bearings

- Linear Roller Bearings

- Split Bearings

- Plain Bearings

- Sleeve Bearings

FAQs About Bearings

Here are some types of bearings:

1. Ball Bearings – Use small balls to reduce friction.

2. Roller Bearings – Use rollers to support heavy loads.

3. Needle Bearings – Use long, thin rollers.

4. Tapered Bearings – Use tapered rollers for both types of loads.

5. Thrust Bearings – Handle pressure from one direction.

6. Magnetic Bearings – Use magnets to reduce friction.

These bearings help machines move parts smoothly!

Here are 12 top bearing brands known for quality and reliability:

1. SKF

2. NSK

3. FAG

4. Timken

5. NTN

6. Koyo

7. INA

8. Schaeffler

9. ZKL

10. RBC Bearings

11. Nachi

12. JTEKT

These brands are widely used in industries for producing high-performance bearings.

Bearings are named by:

1. Type: The first number shows what type it is (like ball bearings).

2. Size: The next numbers show the size (bigger numbers = bigger bearings).

3. Features: Extra letters show special features (like seals).

Example: 6205-2RS means a ball bearing, medium size, with rubber seals.

A 6203 bearing is a small ball bearing.

1. 6 means it’s a ball bearing.

2. 203 shows the size: 17 mm inside, 40 mm outside, and 12 mm wide.

It’s used to reduce friction in machines.

Read More

- Names of Types of Balls

- Types of Motors

- Metals Names

- Tools Names

- Types of Magnets in English with their Pictures

- Homophones Words List

- Types of Screw Heads